Quality Assurance Business of HiNSHOKEN

Quality Assurance Business

We were established in 1988 as a specialized group responsible for quality assurance of aerospace equipment, and have played a part in the development of the aerospace industry and have grown steadily. Inspectors who have received specialized training are working as inspectors and quality assurance engineers at Mitsubishi Heavy Industries and other aerospace-related companies with the motto of improving the quality of inspections. We will surely move forward step by step toward infinite possibilities.

Thoughts on quality assurance

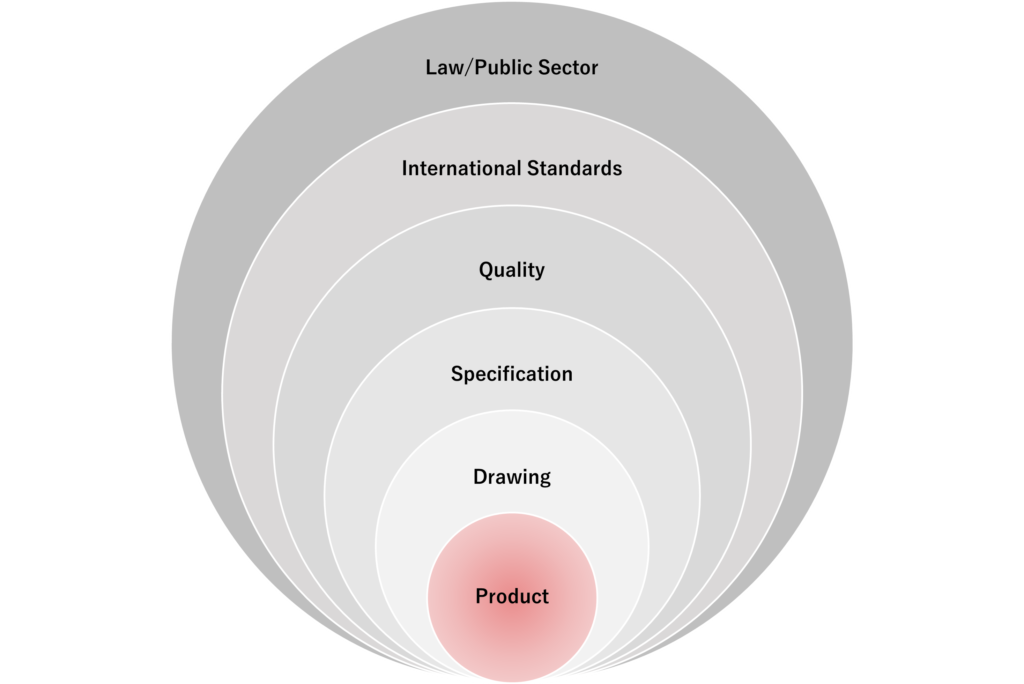

There are various requirements for quality control of aerospace equipment. By manufacturing according to these requirements, the product will be “secure”, “safe” and highly “reliable”. We, HiNSHOKEN, prove that we meet these requirements by various methods, and we believe that “giving life” to the products manufactured by our customers is “Quality Assurance”.

Obtained Nadcap accreditation

- To demonstrate the integrity of aircraft parts (composites, metal materials, etc.), we use ultrasonic and X-rays to inspect the parts for internal defects without damaging them. This is called non-destructive testing.

- In the aerospace industries, special processes including this non-destructive testing can be examined by an inspection body and publicly proved to be a capable company. This is called the Nadcap accreditation system.

- We have established a system that conforms Nadcap requirements and obtained Nadcap accreditation (NDT) for non-destructive testing in February 2007.

Obtained JIS Q 9100 certification

What is JIS Q 9100?

JIS Q 9100 “Quality Management System-Requirements for Organizations in the Fields of Aviation, Space and Defense” is managed by aerospace-related manufacturers with quality first in a series of operations from development to manufacturing and delivery. It defines the requirements necessary to build a so-called quality management system (QMS).

In the 1990s, the ISO 9000 series became a hot topic and became widely certified not only in the manufacturing industry but also in the financial / service industry, construction industry, transportation industry, etc., but this ISO 9000 series is special for aerospace products. JIS Q 9100 is the one with the additional request.

Obtained JIS Q 9100 certification

We consider it essential for our company, whose business is quality assurance, and in July 2000, we obtained ISO 9002 certification, and in July 2003, we obtained JIS Q 9100 certification.

For these reasons, we proceeded with preparations and obtained JIS Q 9100 certification in July 2003.